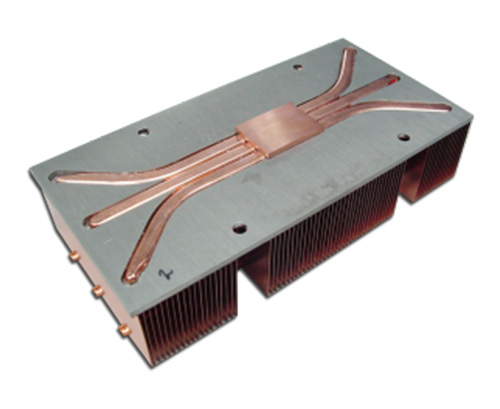

The Snap Fit In + Pipe is a precision-engineered, quick-connect component designed to simplify and accelerate installation in custom heating and cooling systems. It combines a snap-fit connection interface with integrated copper or aluminum tubing, providing a secure, leak-tight joint without the need for brazing, welding, or specialized tools. This innovation is ideal for modular HVAC systems, heat pumps, refrigeration units, and process cooling equipment that require efficient assembly and maintenance access.

Each Snap Fit In + Pipe assembly is custom-designed for the specific pressures, flow rates, and layout needs of the project, offering significant time and labor savings while maintaining system reliability and thermal performance.